In this update, we begin fitting the cowling.

Rough fitting of the cowling top to bottom . The top and bottom have been cut to the scribe lines , this gets the close to final fit . The mating edges are now sanded removing small amounts of material to get to the finish fit . This process requires a lot of assemble , mark , sand, reassemble and so on. Only small adjustments are made here ( aim small - miss small )

Fitting the cowling to fuselage . Same process as above make small adjustments as you go . The cowling will come off and back on many times before you get the fit you want . The space behind the back spinner bulkhead is 1/8 at the top 3/16 center and 1/4 at the bottom , this gap will even out during the first 100 hrs of operation as the engine settles in the mounts .

The rivet locations are transferred from the fuselage to the cowling and #40 holes are drilled in the fiberglass . Holes are then drilled into the underneath hinges . Parts are then dissembled countersunk and a coat to epoxy applied to the inner cowling surfaces .

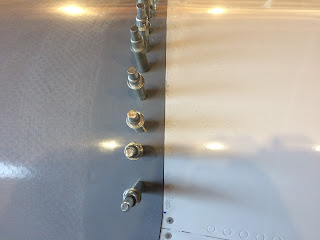

All hinges are riveted to cowling

No comments:

Post a Comment