|

| RV14 Knife edge to accommodate some riveting. |

|

| Tailwheel spring mount! |

|

| Basement is getting smaller! |

|

| Starting on the tailcone. This bulkhead is match drilled and deburred and dimpled. |

|

| Elevator counterweights are installed. |

|

| Elevators are fun. |

|

| Ready to rivet! |

|

| This is how I rooooollllll...elevator leading edges. |

|

| I inherited my Uncle's WWII bomber jacket...the real deal! |

|

| My Bücker buddy Jerry was in town so we went to visit John Downing and his amazing Jungmann. |

|

| This is where the RV will be based one day. |

|

| Weight is added to the aft elevator skins to keep everything in contact while the pro seal dries for a few days....taking Memorial Day weekend off from building. |

|

| After applying pro seal to the foam elevator aft ribs, and 3M tape to the trailing edge wedge, I clecoed the trailing edge together. |

|

| Here I use a special bucking bar, specially situated to rivet the Elevator skin to the spar. |

|

| Here I attach an elevator skin on the right elevator. |

|

| Elevator trim tab complete. |

|

| Here I rivet the elevator tip ribs together. |

|

| Weight to hold the trim tab together while the proseal on the ribs cures. |

|

| Clecoing the trim tab actuator doubler. |

|

| Dimpling the elevator trailing edges. |

|

| Looks can be deceiving. The elevators go together for match drilling, then come apart for debarring, scuffing and priming. So I get to assemble them twice. |

|

| Installing pulled rivets in the HS rear spar. I love this pneumatic pop rivet gun. And I didn't go crazy. $80.00 from Northern! |

|

| Hiding out! |

|

| HS skin goes into the cradle. |

|

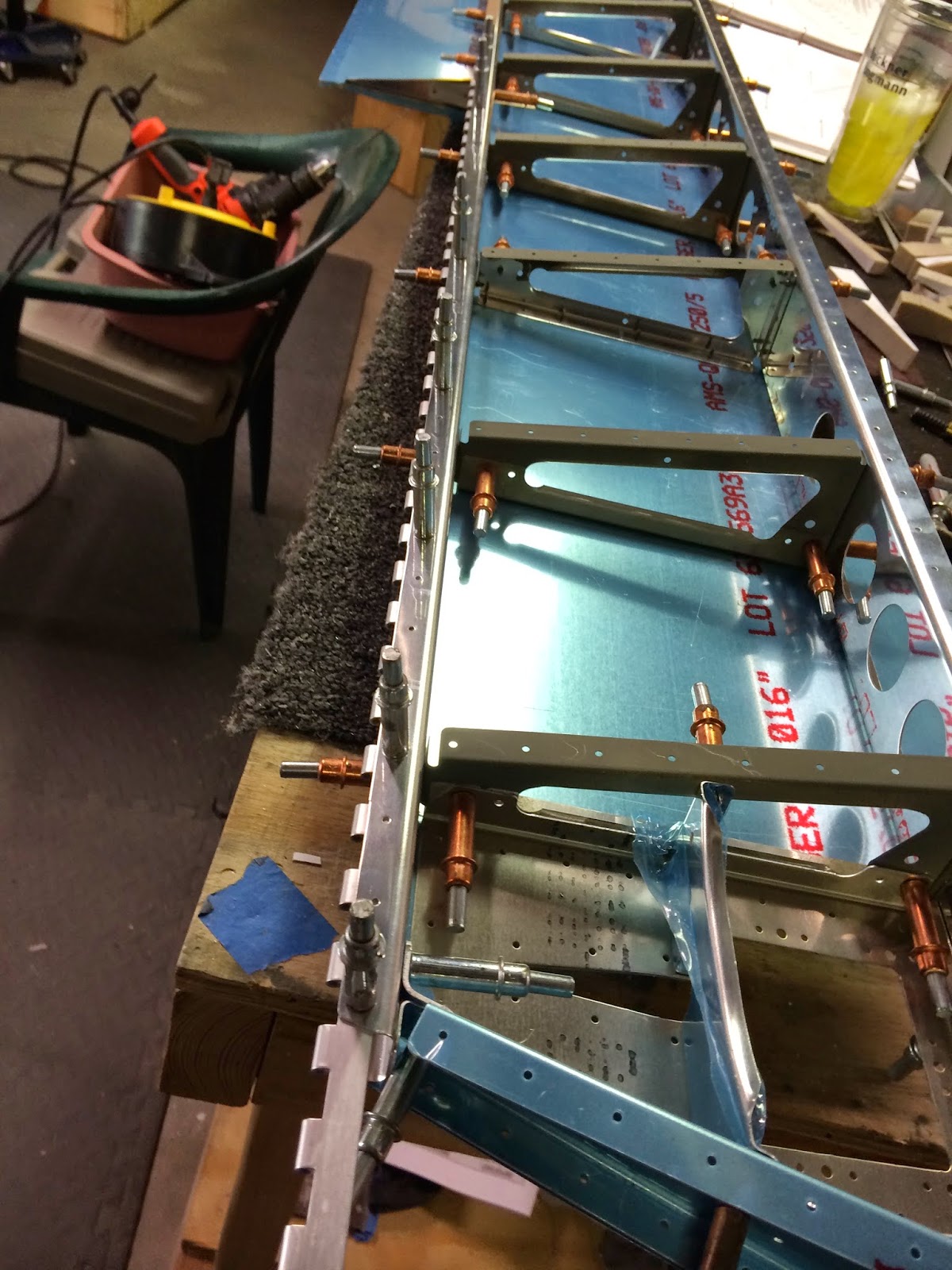

| The Horizontal Stabilizer going together. |

|

| Here I countersink a HS spar. |

|

| This is REAL airplane building. Brian Karli and Richard Epton hand form a Sopwith Camel cowl. No pre punched holes here! |